Blogs

Application of Welding Robots in Medical Bed Manufacturing

Introduction

Welding robots have revolutionized various manufacturing industries, and the medical bed manufacturing sector is no exception. Laser welding machines, a specific type of welding robot, have become increasingly prevalent in this industry due to their precision, efficiency, and versatility.

Laser welding uses a high-powered laser beam to melt and join metal parts. This technology offers several advantages over traditional welding methods, including higher precision, deeper penetration, and the ability to weld complex geometries and dissimilar materials. Laser welding machines are particularly well-suited for the intricate and demanding requirements of medical bed manufacturing.

Working principle:

The bed frame welding workstation adopts a single-machine dual-station layout. While the robot is welding at one station, the other station can clamp and unload the workpiece, and the cycle is repeated. By reasonably configuring the operators, the efficiency of the system can be maximized. The bed leg welding workstation adopts a three-station layout. While the robot is welding at one station, the other two stations can clamp and unload the workpiece, and the cycle is repeated. By reasonably configuring the operators, the efficiency of the system can be maximized.

Product application advantages:

1. The welding unit has a simple configuration and flexible layout. It can be arranged according to the actual situation, effectively avoiding the interference of the fixture, dual-station configuration, flip positioner and tooling fixture, stabilizing and improving the welding quality, and better ensuring high-quality welding.

2. It is suitable for mass production of products, and the welding of workpieces with many welds and non-centralized positions can ensure the accessibility and status of the welding gun through the flipping of the positioner and the change of the robot’s own gun posture, whether it is a straight line, arc or other complex welds.

3. The dual-station layout improves production efficiency. It can effectively prevent the idle time of the robot when the workpiece is disassembled, improve the efficiency of the robot, and ultimately improve its production efficiency. This system is designed to adapt to the two-shift work system, with each shift working for 8 hours, and the equipment can meet the 24-hour three-shift continuous operation capacity.

4. Flexible configuration, can be customized according to customer needs. The corresponding configuration can be selected according to the needs of the product: such as the robot system brand. Welding power supply brand, etc.

5. High flexibility, shortened product update cycle, cost saving. The preparation cycle for product modification and replacement is shortened (only the software and necessary fixtures need to be modified, etc.), and the corresponding equipment investment is reduced.

Product structure:

The bed frame welding workstation includes a long-arm welding robot FD-V6L, a robot mounting base, a single-axis pneumatic positioner, a welding fixture (designed and manufactured for customer workpieces), a robot control system, a robot teach pendant, a welding power supply, a robot-specific welding gun, and an external control box.

The bed leg welding workstation includes a short-arm welding robot FD-V6, a robot mounting base, a bed leg welding fixture (designed and manufactured for customer workpieces), a robot control system, a robot teach pendant, a welding power supply, a robot-specific welding gun, and an external control box.

Product recommendation:

Product combination: Industrial Robot Welding Worksation & JS-HWN Handheld Welding Machine

The use of laser welding robots can perform batch work efficiently and accurately, and can also save labor. In order to achieve better product effects, adding handheld welding machines to check and fill in the gaps in the formed products can avoid missing welds in the corners caused by the welding blind spots of the laser welding robots. This solution can perfectly solve this industry problem.

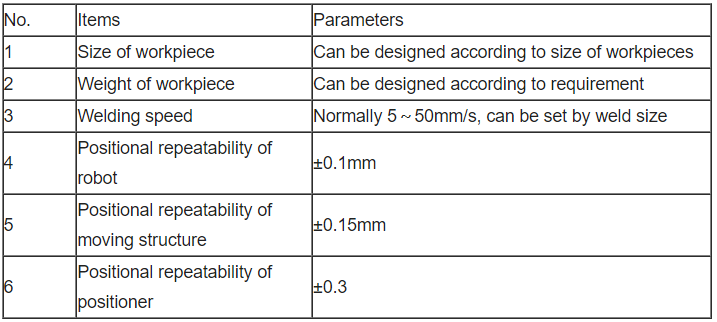

Product parameters:

Conclusion:

Laser robots have many advantages over traditional welding robots, making them the best choice for industries such as medical bed manufacturing that require high precision, high efficiency and high quality. The speed and efficiency of laser welding robots can increase productivity and reduce costs, while their precision and accuracy ensure high-quality welding.

The welds produced by laser welding robots are stronger and cleaner, which can improve the durability and aesthetics of the final product, while the reduced heat-affected zone can maintain material properties. The versatility and flexibility of laser welding robots enable them to weld a variety of materials and complex geometries, and their advanced automation functions can improve overall productivity and workplace safety.

As the demand for high-quality medical beds continues to grow, the adoption of laser welding technology is likely to increase, driving further innovation and efficiency improvements in the industry.

JNJSINDUSTRY

China Leading Laser Welding Machine Manufacturer

We Follow Best Sevices

JNJSINDUSTRY focus on product quality and customer service

Attitude determines success or failure

- Technology Guidance

- Two-year warranty

- On-site training

- Maintenance guid