Introduction:

In the modern era, technology has become an integral part of every industry, including the kitchen and bathroom sector. Among the various technological advancements, laser welding machines have emerged as a game-changer, offering precision, efficiency, and versatility. This article explores the application of laser welding machines in the kitchen and bathroom industry, revolutionizing manufacturing processes and product quality.

1.Overview of Laser Welding Technology:

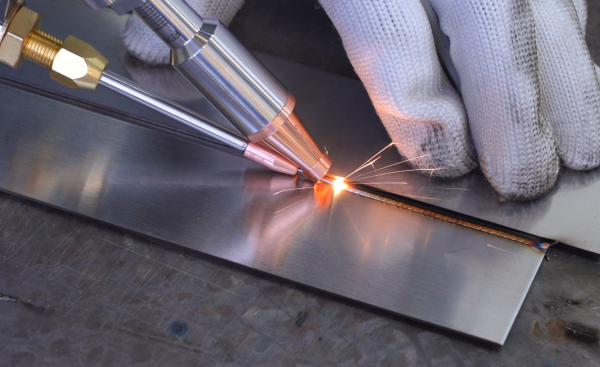

1.Laser welding utilizes a concentrated beam of light energy to join materials together.

2.It offers several advantages over traditional welding methods, including minimal heat-affected zones, precise control, and high welding speeds.

3.Various types of lasers, such as fiber lasers, CO2 lasers, and solid-state lasers, are used in industrial applications.

2.Applications in Kitchen Manufacturing:

a.Stainless Steel Fabrication:

b. Cabinet Production:

c. Cookware Manufacturing:

1.Manufacturers utilize laser welding for bonding handles, spouts, and lids to cookware bodies.

2.The welds provide leak-proof seals and enhance the durability of the products.

1.Laser welding is employed in the assembly of cabinet components, including hinges, handles, and drawer slides.

2.It enables seamless joints without the need for additional finishing processes, improving efficiency and reducing production costs.

1.Laser welding machines are widely used in the fabrication of stainless steel components for kitchen appliances like sinks, faucets, and countertops.

2.The precise and clean welds ensure structural integrity and aesthetic appeal.

3.Impact on Bathroom Fixture Production:a. Shower Enclosures and Doors:b. Faucets and Bathroom Accessories:c. Bathtub and Shower Tray Manufacturing:

1.Laser welding plays a crucial role in bonding acrylic or fiberglass panels to form bathtubs and shower trays.

2.The seamless welds enhance the durability and appearance of the fixtures, meeting stringent quality requirements.

3.Faucet assemblies and bathroom accessories often require intricate welding of small components.

4.Laser welding machines offer the precision and control needed for joining delicate parts while maintaining the aesthetics of the final products.

5.Laser welding technology is instrumental in the fabrication of shower enclosures and doors made of glass and metal frames.

6.Precise joints ensure water-tight seals and structural integrity, meeting quality standards and customer expectations.

4.Advantages of Laser Welding in the Kitchen and Bathroom Industry:

a. Precision and Quality:

Laser welding ensures precise, high-quality joints with minimal distortion, leading to superior product performance and aesthetics.

b. Efficiency and Cost Savings:

The high welding speeds and minimal post-processing requirements result in improved efficiency and reduced production costs.

c. Versatility and Flexibility:

Laser welding machines can handle a wide range of materials, thicknesses, and geometries, offering flexibility in product design and manufacturing.

d. Environmental Sustainability:

Compared to traditional welding methods, laser welding consumes less energy and produces fewer emissions, aligning with sustainability initiatives.

5.Future Trends and Innovations:

a. Integration of AI and Robotics:

The integration of artificial intelligence (AI) and robotics with laser welding systems enables autonomous operation and adaptive control, further enhancing efficiency and quality.

b. Advancements in Laser Technology:

Ongoing research and development in laser technology are leading to more powerful, efficient, and cost-effective laser welding systems, expanding their applicability in the kitchen and bathroom industry.

c. Customization and Personalization:

Laser welding facilitates customization and personalization of kitchen and bathroom fixtures, allowing manufacturers to meet the diverse preferences of consumers.

Now more and more companies to devote themselves to the laser industry, with the development of science and technology market progress, part of the enterprise was eliminated, the excellent enterprise to get the inheritance, can make use of better scientific research team, after-sales team, sales team so that we all walks of life to feel the laser industry change and progress, enjoy the laser industry into the progress of the industry brought about by the change and convenience.

Conclusion:

Laser welding machines have emerged as a transformative technology in the kitchen and bathroom industry, offering precision, efficiency, and versatility in manufacturing processes. From stainless steel fabrication to shower enclosure assembly, laser welding enhances product quality, efficiency, and sustainability. As technology continues to evolve, laser welding is poised to drive further innovation and excellence in the design and production of kitchen and bathroom fixtures.