Introduction:

Laser welding heads are essential components in achieving precise and efficient welds across various industries. In this article, we will compare two types of laser welding heads: the wobble laser welding head and the galvanometer laser welding head. By understanding their differences, manufacturers can make informed decisions regarding the most suitable welding head for their specific applications.

1.Welding Performance:

Wobble laser welding heads excel in applications with challenging joint geometries, irregular gaps, or dissimilar materials. The oscillating motion improves heat distribution, resulting in reduced distortion and minimized heat-affected zones.

2.Weld Quality:

Wobble laser welding heads provide improved heat distribution, resulting in strong welds with reduced distortion. The wobbling action helps distribute energy evenly, contributing to better joint integrity.

3.Application Versatility:

Wobble laser welding heads are advantageous in applications with irregular joint configurations, uneven gaps, or dissimilar materials. Their ability to accommodate variations in fit-up and joint conditions makes them suitable for a wide range of challenging welding scenarios.

4.Speed and Efficiency:

Wobble laser welding heads, while effective in challenging applications, may have slightly slower welding speeds due to the oscillation motion. However, they compensate with enhanced gap bridging capabilities, providing reliability in demanding welding scenarios.

Today, based on the known use of laser welding, we provide manufacturers with better laser head solutions for raw materials with thick plates and wide welds.

The specific parameters are as follows:

Attributes | BWT20 | BWT21 | BW101 |

Acceptable Power | 2kw/3kw | 2kw/3kw | 2kw |

Light Aperture | 9mm | 9mm | 8mm |

Swing Amplitude | 0-5mm | 0-5mm/0.1-12mm | 0-5mm |

Overall Weight | 0.85kg | 0.75kg | 1.0kg |

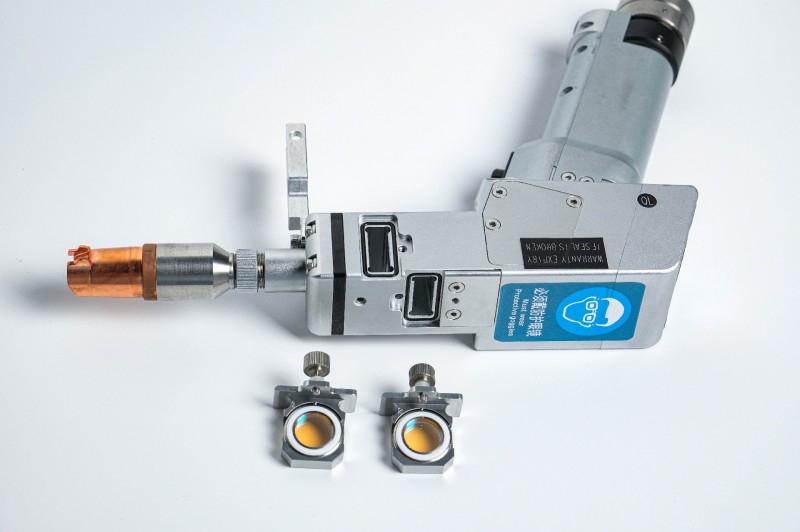

Product advantages

- Pump-controlled double protective glasses, combined lenses, easy to replace

- Scientific cooling system, compatible with water cooling and air cooling

- Up to 26 languages ,can be selected

- Data storage, process package has storage and call function

- Laser power can be selected and automatically matches the corresponding process package

Eight optional operation modes, swing frequency and angle can be set

- Fault monitoring, can quickly check, report in advance, and prevent in advance

- The gun comes with a small screen for easy viewing and debugging

- Welding parameters, wire feeder parameters, can be remotely controlled (BWT20S)

- Fish scale pattern double wire feeding welding, welding width up to 14mm (BWT21)

Wobble heads excel in accommodating joint variations and providing enhanced gap bridging capabilities, Manufacturers should consider their specific welding requirements and evaluate the benefits and limitations of each type to select the most appropriate welding head for their applications.