INDUSTRY

Application of Laser Welding Technology in Steel-Wood Furniture

Background Foundation

Steel-wood furniture is widely used in people’s daily life due to its superior performance and low production cost. It uses a frame made of steel square tubes as the main frame, and sets wooden boards on the surface of the main frame. The production of steel-wood furniture includes cutting, punching, assembly, welding and other process steps of the pipe.

The existing production method is mainly for production personnel to complete the above-mentioned multiple process projects by manual operation. This small workshop-style production method has a low cost advantage, but many companies will optimize process technology with continuous progress to achieve the purpose of product optimization.

Of course, some large factories will also use automatic production lines to further improve the production efficiency of steel-wood furniture and reduce its production costs. In order to increase the automation rate of steel-wood furniture production, the specific method selection depends on the strength of the enterprise and factory, funds, personnel and other aspects.

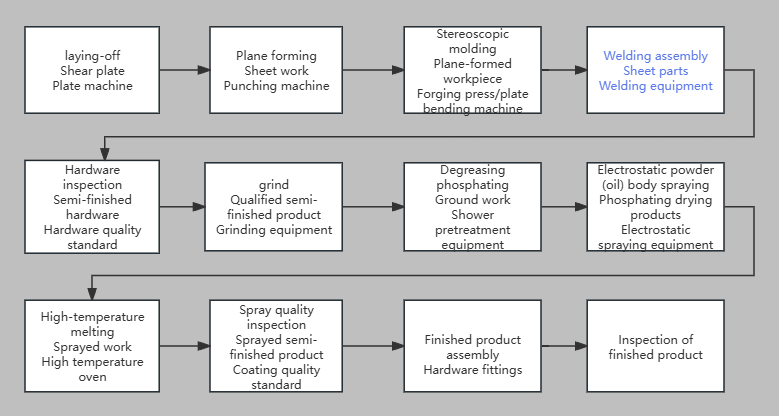

Steel-wood furniture production process:

Difficulties in welding in the industry:

Material compatibility: Due to the different thermal and physical properties of metal and wood, it may be challenging to ensure a strong bond between metal and wood.

Thermal management: Controlling heat input is the key to preventing damage to wooden parts. Overheating can cause warping, burning or discoloration.

Joint design: The design of the joint must be carefully considered to ensure proper alignment and strength. This may require specialized fixtures and tools.

Cost: The initial investment in laser welding equipment can be high. However, the long-term benefits in terms of efficiency and quality often outweigh the initial cost.

Advantages of laser welding machines compared to other welding machines:

MIG/TIG welding: Metal inert gas (MIG) and tungsten inert gas (TIG) welding are two common welding methods used in metal fabrication. However, they require a high level of skill and precision.

MIG welding, which can cause spatter, can damage the wooden components of steel and wood furniture.

Although TIG welding is highly accurate, it is slower and less efficient than laser welding.

Resistance welding: This technology uses an electric current to heat and join materials. While effective for some applications, it causes significant thermal deformation and is not suitable for delicate or complex work, limiting its use in the steel and wood furniture industry.

Friction welding: Friction welding uses mechanical friction to generate heat and join materials. This method is limited to specific types of joints and materials and is generally not suitable for the diverse needs of steel-wood furniture manufacturing

Advantages of laser welding machines in the steel-wood furniture industry:

Precision: The laser beam can be precisely controlled, allowing for complex and delicate welding tasks. This is particularly beneficial for creating complex designs and ensuring a high-quality finish in furniture manufacturing.

Speed: Laser welding is much faster than traditional methods. This increased speed translates into higher productivity and shorter manufacturing times.

Minimal deformation: The focused nature of the laser beam results in a minimal heat-affected zone, reducing the risk of deformation and damage to surrounding materials. This is critical when working with materials like wood, which can be easily damaged by overheating.

Flexibility: Laser welding can be used to join a wide variety of materials, including different types of metals and even different materials. This flexibility is particularly useful in steel-wood furniture, where metal components need to be firmly attached to wooden components.

Automation:Laser welding systems can be easily integrated with automated manufacturing processes, further improving production efficiency and consistency.

Product recommendation:

JS-HWN LASER WELDING MACHINE

◆ Multi-functions: welding, cleaning,cutting 3 in 1

◆ Portable size, easy to move

◆ High-precision accuracy for joining even small parts

◆ Faster welding speed: 4 TIMES than traditional welding

Conclusion:

Laser welding technology has revolutionized the steel-wood furniture industry by providing a precise, efficient and versatile method of joining materials. Although there are challenges that need to be addressed, the advantages of laser welding make it a better choice compared to traditional welding techniques. As the technology continues to advance, laser welding is likely to become an integral part of the manufacturing process in the steel and wood furniture industry, thereby improving product quality and manufacturing efficiency.

JNJSINDUSTRY

China Leading Laser Welding Machine Manufacturer

We Follow Best Sevices

JNJSINDUSTRY focus on product quality and customer service

Attitude determines success or failure

- Technology Guidance

- Two-year warranty

- On-site training

- Maintenance guid